The milling is a process of metal-removing by feeding the workpiece passes through

the rotating multipoint cutter.

This machine can hold one or more cutters at a time and rotates at high speed to

remove the metal at a faster rate.

The metal removal rate is faster as compared to a lathe machine.

This machine is used to make gears like Spur gears, and also drill the workpiece bore,

and produce slots.

Types of milling machine

The milling machine may be classified in several forms, but the choice

of any particular machine determined primarily by the size of the

workpiece.

A/c to the general designed, the distinctive types of milling machines

are:

1)Column and knee type milling machines

2)Planer milling machine

3)Fixed bed type milling machine

4)Special type of milling machine

5) Production Milling Machine

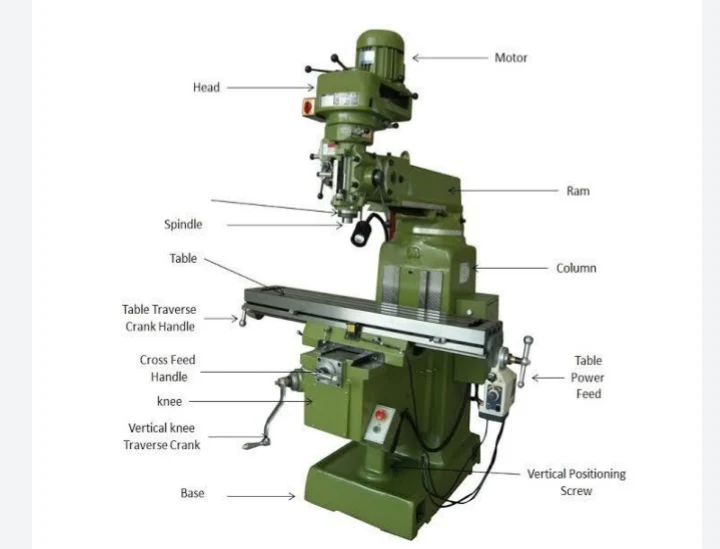

PARTS OF MILLING MACHINES

1) Base:

The base is the part upon which the whole machine parts are being

mounted. It is a type of foundation for the machine.

The base is mostly made up of cast iron, so it has good strength and

rigidity. It also helps in the absorption of shocks, Cutting fluid can also

be stored in the base.

2) Column:

The main supporting frame which consists of all the driving

mechanisms and the motor is called the column.

The driving mechanism usually consists of a cone pulley mechanism in

which the v-belt is being used to connect it to the motor.

Further by using this driving mechanism the speed of the machine can

control as per our requirement.

3) Knee:

The knee shape is quite similar to that of the human body knee. This is

an important part of this machine that supports the other parts like the

saddle and table.

It is attached to the column and has guideways by which it can move up

and down with the help of the elevating screw for adjusting its height.

4) Saddle:

The saddle is present on the top of the knee which further carries the

table. Its basic function is to support the table.

A saddle can slide on the guideways which are exactly at 90 degrees to

the column face. Saddle moves crosswise (in or out) on guideways

provided on the knee.

5) Table:

The table is present on the top of the saddle. The table consists of T-slots

or sometimes fixtures are used for holding up the workpiece on the

table. A table can travel longitudinally in a horizontal plane.

6) Over-arm:

It is also called the overhanging arm. Overarm is present at the top of

the column.

The basic function of the over-arm is to support the arbor

and spindle.

7) Spindle or Arbor:

The top portion of the column contains the spindle.

The spindle is also

an important part of the machine as it is the part where the multipoint

cutter is attached.

Power required for the rotation of the spindle is obtained from the

motor through the belt, gear, and clutch assembly.

Milling Machine disadvantages with remedies:

The disadvantages of the milling machine are as follows:

High Flank wear: It has a high flank wear rate which can be prevented by

reducing speed and increasing the feed rate. Further to avoid it one should use

harder carbide with proper geometry and sharpened cutting edges.

High crater wear: High crater wear is found which can be tackled by reducing

speed and using harder carbide.

Breaking of carbide:

Sometimes the production process gets hindered

because of the breaking of the carbide. The remedy for this problem can be the

use of tougher carbide, and rigidity of the cutter, machine, and arbor should be

ensured.

High Chatter: This happens due to poor rigidity of cutter, machine, loose

arbor, and improper geometry.

This situation can be improved by increasing

feed, reducing speed, and using unequal pitch cutters.

Chip clogging: The milling machine also suffers from the problem of chip

clogging which can be reduced by using reducing the number of

● Milling Machine Operations:

The following Operation is performed by the Milling Machine:

● Plain or Slab Milling Operation

● UP and DOWN Milling Operation

teeth on the cutter and increasing speed and chip pockets.

● #1. Plain Milling or Slab Milling Operation:

Plain or slab milling is a process in which the plain, horizontal or flat surfaces

are produced, which are parallel to the axis of the rotation of the cutter. A

peripheral mill cuter is used for performing the slab milling operation.

Principle of milling machine

In milling machine, the metal is cut by means of a rotating cutter having

multiple cutting edges for cutting operation. The workpiece is fed against the

rotator cutter.

Workpiece moves against the cutting edges of milling cutter machined surface

is formed in one or more passes of the work the work to be machined is held in

a vice,

a rotator table, a three jaw chuck, an index head, between centers in a

special fixture or bolted to machine table.

The rotatory speed of the workpiece depend upon the type of material being

machined.

0 Comments

Thank for you comment